The all grain BIAB American Pale Ale I made on my last brew day is delicious. Simply wonderful. Even not fully carbonated it’s awesome with a great malt character, much more so than any beer I’ve made to date. So of course I’m making another batch with a few variations. This time I want to shoot for something a bit drier, more malt character, an less bitterness. I suspect the hop-stand of Cascade at the end of the boil is adding more bitterness that I’d like. Basically I’m looking for a recipe that is more drinkable in the up-coming summer months. To achieve these aims I’m going to mash at a bit lower temperature (to extract more fermentable sugars from the malted grain), replace the crystal/LDME with Munich I malt, and decrease the initial Magnum hop addition by two grams.

Bairds Golden Promise 2.5kg

Munich Malt I 0.35kg

10g Magnum @ 60 minutes (12.7%AA)

18g Cascade @ 10 minutes (5.6%AA)

12g Cascade @ Flameout for 10 minutes (5.6%AA)

SAFALE US-05 harvested from last brew

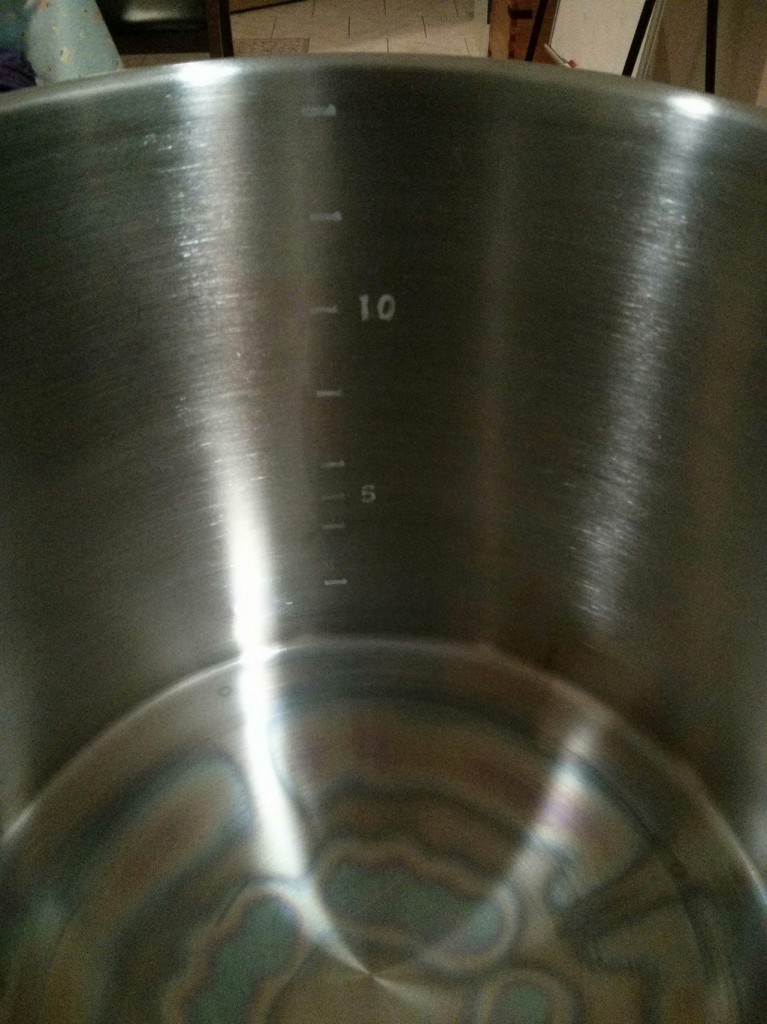

Brew Type : 12.5L All Grain (BIAB)

OG: 1.050

FG: 1.013

ABV: 5.1%

IBU: 30.7

EBC: 10.1

Method:

Heating the Strike Water

1. Bring 8L of water to strike temperature of 72C with grain bag lining pot. Extra reading I’ve done since my last brew suggested my mash was too thin so I’ve dropped the strike water by 2L.

Mashing In!

2. Add grain bill, stir to ensure no dough balls.

Using my Keg King Controller to Take the Mash Temperature

3. Took temperature of mash (66.5C) replaced lid on pot, and wrapped pot in doona for 60 minutes to mash.

4. Bring 8L of water to 75C in another pot.

5. At the end of 60 minutes unwrap pot, take temperature again (62.3C). Remove grain bag from pot and suspend over pot on wire tray and allow to drain out. At this point there was 6L of wort in the pot.

6. Batch sparge with the half wort and half the 75C water and allow to drain. Sit bag in remainder of 75C water, drain, empty wort empty into pot, squeeze out bag again.

Bringing Wort to the Boil

8. At this point I had 13.5L of wort and drew a small sample for take a gravity reading (1.035 at 51.7C). I’ve bought some FERMCAPs which is supposed to stop boilovers so I can get more wort in my 15L pot. I added 6 drops of the FERMCAPs to pot and now I could bring the pot to the boil and make the first hop addition. This brew I decided to make little muslin bags to put my hops in so I didn’t need to strain out the debris when putting the wort into my fermentation vessel.

Hop Additions (10g Magnum, 12g Cascade, 18g Cascade)

Hop Additions in Baggies!

9. At 50 minutes make second hop addition.

10. At flameout add third hop addition and whirlpool and leave for 10 minutes. There was a 2.5L loss during the boil.

11. Chill wort in ice bath to 25C.

S05 Yeast Starter

12. Top up to 12.5L with cool boiled water, take starting gravity reading and aerate wort with spoon. I harvested some S05 yeast from my last brew and got things moving along with a 500mL starter. I drained off the expended wort from the top of the starter, replaced it with a bit of my new wort, shook it vigorously and then pitched into my vessel. I put the lid on the fermenter, filled the airlock with sanitizer and put it all in my temp controlled fridge with a set temperature of 18.5C.

Let’s Ferment!

My measured OG was 1.046 @ 24.2C which corrects to 1.047. Not too far of my target of 1.050, the difference is explainable as my BIAB efficiency is not as high as the calculator I am using to develop my recipes.

Mash Efficiency

2.5KG of Golden Promise Malt has a potential of 1.038 points per gallon. I’ve got 5.5lb of grain in 3.56 gallons of water so the potential for the GP is 58.71 points.

0.35KG of Munich I malt has a potential of 1.037 points per gallon. 0.35*2.2*37/3.56 leads to a potential for the Munich Malt of 8.21 points.

So, there’s potential of 66.92 points (58.71+8.21) and the measured pre-boil gravity of 1.045 (45 points) gives 67.25% (45/66.92) efficiency.

Other Notes

I used the Brewers Friend Mash Temp Calculator to arrive at my strike temperature of 72C. Assumption was made that there’d be 1L of water absorption per kilo of grain. The targeted pre-boil volume was 13L so this is how I arrived at the 8L of sparge water (13L boil – 8L strike + 2.85L absorption, about 8L). Note to self, must weigh down hop bags with marbles or they float at the top of the boil. Other note to self, the 4C drop during the mash was probably due to the doona being cold. Either think about building a simple mash tun from an esky or pre-heat dooa with a pot full of hot water. I can use the hot water to sparge anyway so there’s no waste.

Fermentation Notes

Fermentation commenced within 12 hours of pitching and I really only saw activity in the airlock for a day.

20/9/15 – Drew a sample and took the gravity, 1.009.

Drinking Notes

I’ve been holding off on commenting on this beer for a while hoping it would improve (or I’d learn to like it). On the eye it’s a nice looking beer, a pale gold and just a little cloudy, not as cloudy as, say, a Coopers Pale Ale, but more cloudy than a lager. On the nose it’s decent too, with hints a bread and just a bit of lemon or citrus from the Cascade hops.

The first mouth full is good too, with a massive up front malt hit. However from that point forward it’s all down hill. The initial malt hit lessens in intensity and there’s just not enough bitterness. Couple that with, what I can only call wateriness and an unpleasant taste in the mouth after half a pint and it doesn’t make for a particularly enjoyable beer. I’m not sure what the issue is but I’m thinking there’s three main factors:

- The grain was of questionable quality. First time I’ve bought grain from that particular LHBS and there’s no telling how hold it was. I’ve bought hops from them once before and it was not great either.

- My mash temperature control was awful, I dropped way too much temperature.

- Not enough Magnum meant not enough bitterness.

I’ll drink what’s left but I’m keen to move forward with another brew and sort out these issues.

What Next

I’d like to try the same beer with grain from the other LHBS (which is usually pretty good), a few grams more hops at 60 minutes, and with better temperature control on the mash.

There’s some chill haze but I’m putting that down to the poor effort I made cooling the wort due to poor planning on my behalf.

There’s some chill haze but I’m putting that down to the poor effort I made cooling the wort due to poor planning on my behalf.